The basics of shock absorbing

What is a pressure surge?

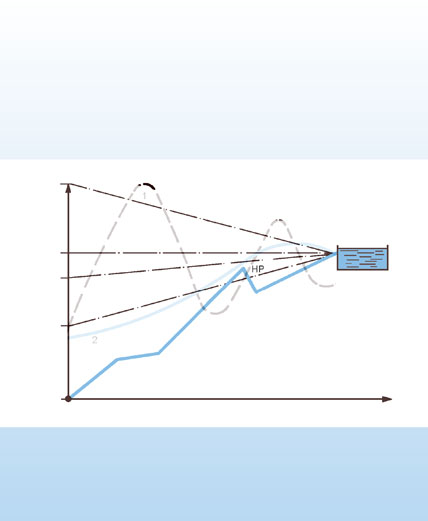

A pressure surge (also called water hammer) is a brief high increase or drop in pressure. It only lasts for fractions of a second, but the pressure peaks occurring can be many times the operating pressure. The peak values that arise can come in the form of both overpressure and negative pressure (cavitation). The propagation speed of the pressure waves can be up to 1400 m/s and depends on the material and the wall thickness of the pipe.

How do pressure surges arise?

Pressure surges in pipework occur due to sudden changes in liquid flow:

- Acceleration of liquid mass when pumps are switched on

- Breakdown in the delivery flow when pumps are switched off

- Abrupt stopping of a liquid that was in motion due to a quick-closing valve

- Sudden change in the direction of flow due to solenoid valves

- Abrupt change in the pipe cross-section due to narrowing or restriction

Where do pressure surges occur?

Pressure surges can arise in any pipe network:

- In the pumping house (when switching on and off or if the power supply to the pumps fails)

- In hydrants for fire-fighting lines

- In filling or metering lines (concrete factories, chemical plants, large laundries, etc.)

What effects do pressure surges have?

- High increase in pressure or negative pressure (cavitation)

- Disturbing noises

- Signs of material fatigue

The consequences are:

- Damage to integrated instruments and fittings

- Breaks in pipework, noise and vibrations

- Loosening or unsealing of joints

How do we prevent pressure surges?

In every system where pressure surges are to be expected or already present, they can be prevented by mounting a correctly dimensioned and low-maintenance ORELL shock absorber.

OLD 0200 - General Bladder accumulator with bladder low-pressure series Typ EBV (149.4 KiB)

OLD 0200 - General Bladder accumulator with bladder low-pressure series Typ EBV (149.4 KiB) OLD 0300 - General Bladder accumulator with bladder high-pressure series Typ EHV (150.8 KiB)

OLD 0300 - General Bladder accumulator with bladder high-pressure series Typ EHV (150.8 KiB) OLD 0400 - General Shock absorber with bladder Typ DDV-DDH (1.8 MiB)

OLD 0400 - General Shock absorber with bladder Typ DDV-DDH (1.8 MiB) OLD 0600 - General Pressure vessels / Expansions vessels with bladder Typ DDV (1.3 MiB)

OLD 0600 - General Pressure vessels / Expansions vessels with bladder Typ DDV (1.3 MiB) OLD 0700 - General Waste water shock absorber with bladder Typ DDA (690.3 KiB)

OLD 0700 - General Waste water shock absorber with bladder Typ DDA (690.3 KiB) OLD 0810 - General Waste water Shockabsorber without bladder with float switch Typ DDA OB (204.5 KiB)

OLD 0810 - General Waste water Shockabsorber without bladder with float switch Typ DDA OB (204.5 KiB)

OLD 1305 - Operating instructions for pulsation dampers (136.7 KiB)

OLD 1305 - Operating instructions for pulsation dampers (136.7 KiB) OLD 1310 - Repair instructions series EHV (664.2 KiB)

OLD 1310 - Repair instructions series EHV (664.2 KiB) OLD 1315 - Repair instructions series EBV (587.1 KiB)

OLD 1315 - Repair instructions series EBV (587.1 KiB) OLD 1320 - Wartungsanleitung Be-/Entlüftungsventile Typ Vannuse-Clapuse (679.4 KiB)

OLD 1320 - Wartungsanleitung Be-/Entlüftungsventile Typ Vannuse-Clapuse (679.4 KiB) OLD 1325 - Mounting instructions Forced Flow (773.9 KiB)

OLD 1325 - Mounting instructions Forced Flow (773.9 KiB) OLD 1340 - Operating manuel Led water level display (327.6 KiB)

OLD 1340 - Operating manuel Led water level display (327.6 KiB)